The effects of using Biocide on a regular basis

Using biocide on a regular basis (maintenance dosing) is not recommended – although, those selling these products will disagree. In fact, maintenance dosing with biocides has been completely removed from the aviation industry altogether.

Using biocide on a regular basis (maintenance dosing) is not recommended – although, those selling these products will disagree. In fact, maintenance dosing with biocides has been completely removed from the aviation industry altogether.

In the past maintenance dosing with biocides made sense to try and safeguard your fuel and equipment when there was no real-time testing alternative available. But, aside from the continual costs involved in maintenance dosing, maintaining the fuel dose rated to the correct levels is an exact science and errors are easily made. Overdosing, particularly with today’s common rail diesel engines, can result in substantial damage occurring with possible affects to the manufacturers warranties.

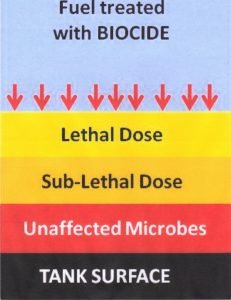

It’s also important to note that Biocides are contact killers. If the infection/contamination is heavy the biocide may not kill all live microbes in the system. What you may find is the top layers receive the lethal dose, the middle layers a sub-lethal dose and the bottom layers (those against the tank floor or walls) are unaffected as there is little to no contact with the Biocide. If dosing rates are not correct or maintenance dosing is done over long periods of time, microbes can develop into resistant strains meaning even higher doses or a product change is required. Also, if any Free Water is present the biocide can, and will, phase/drop out into the water. This is what most are designed to do, as the water holds the vast majority of the microbial material. However, if this mix is drawn up by the fuel pick-up lines and into the engines fuel reticulation system, it can cause substantial damage to the fuel pumps and injectors.

Biocides are most effective as a ‘shock’ treatment and should only be used when you know you actually have a bug problem. The FUELSTAT test kit offers you this opportunity with its alert levels and gives you the results in 10 MINUTES, thereby allowing you to save your resources for when you really need them.

Effects of Biociding

Q: We routinely biocide our storage tanks, what added value would the FUELSTAT™ test offer us?

This question supposes that the system you currently operate includes draining water and then biociding the fuel in the storage tank. Draining the water from the tanks is the key basis for any control system. However, there are problems associated with maintenance dosing (routine biociding). Firstly, it involves costs in terms of manpower and the biocide itself. Secondly, there can be problems with warranties from engine manufacturers if there is any doubt about the ppm levels of biocide in the fuel. Thirdly, there are health, safety and environmental considerations when using biocides and finally, unless the correct ppm level is maintained continuously, there is a danger that a resistant strain or strains of microbes will be produced. Therefore we suggest that the use of biocides should be restricted to the minimum required to maintain clean fuel i.e. used only when test results indicate live microbial growth is occurring.

The introduction of a monitoring regime using the FUELSTAT™ test kit allows the inspection or maintenance engineers to have real-time information on the state of the tank on which to base decisions for biociding. No resource time or expense is wasted on unnecessary treatment. As the FUELSTAT™ test kit requires only a sample from the tank and takes just 10 minutes to operate, it is a quick, easy and an accurate way of determining when and what treatment is required.

Q: Does the test kit have any reaction with the biocides?

The basic answer to this is “no it does not”. There should be a delay between biociding and retesting to see whether the biocide has been totally effective. We recommend retesting a week to ten days after the biocide has been introduced into a contaminated tank. That would mean looking for traces of any surviving microbes, not the residue from that which has already been killed.